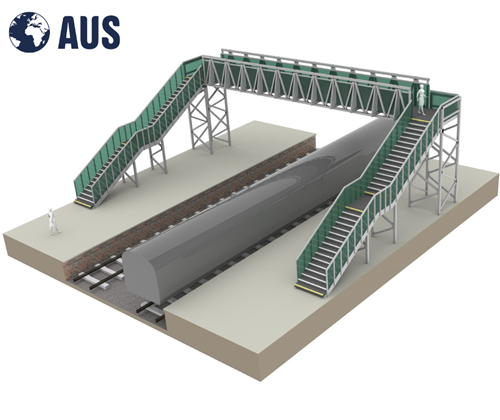

AUS are a market leader in the supply of overhead line components into the rail industry. We are the go-to trusted partner for all of your construction requirements. We value and understand the importance of getting product to site on time every time and we always go the extra mile to exceed your expectations.

AUS are a market leader in the supply of overhead line components into the rail industry. We are the go-to trusted partner for all of your construction requirements. We value and understand the importance of getting product to site on time every time and we always go the extra mile to exceed your expectations.

Innovation is a key driver in moving the industry forward, our passion is to provide solutions to issues in order to improve our railway or ways of working.

We are proud to have been awarded 2 FoaK (First of a Kind) innovation contracts in June 2020. These focussed on innovative projects to help make our railways safer, greener and more reliable. The FoaK schemes are funded by the Department for Transport and facilitated via Innovate UK.

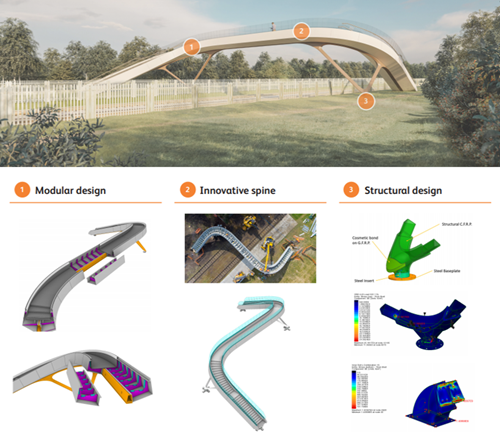

One of our FoaKs aim is to provide a novel, low environmental impact composite railway footbridge. The objective is to demonstrate a new method of connecting fibre reinforced plastic (FRP) together to form a modular footbridge.

This offers huge benefits over existing technology

This project really showcased how effective innovation could be achieved in relatively short timescales when working with SME’s – we were pleased to say we had an operational bridge installed at Rail Live 2021.

Our multidisciplinary design teams work on all stages of a project - from early stage design development and feasibility studies to the detailed design of all railway infrastructure and engineering assets. Nobody knows the railway better than we do.

On our stand we showcased our work across all our design disciplines with a focus on our specialist teams and how we applied the principles of SPEED to early stage design work. We also took to the Network Rail Village Stand to tell guests how our design work made the new FLOW Bridge a reality.

On June 16 at Rail Live, we celebrated the life of Major John Poyntz, who was the last of a long line of Royal Engineer officers to be appointed an HM Inspecting Officer of Railways. John’s illustrious career began in 1955, his first Army posting being to the Longmoor Military Railway. In 1965 he transferred to the newly formed Royal Corps of Transport which had assumed the railway role of the Royal Engineers.

John was to become a major figure in the military railway organisation, both at home and abroad. On retirement, John was recruited into Her Majesty’s Railway Inspectorate, finally retiring in 2006. During his retirement, John gave considerable advice and support to the railway heritage sector. John died of cancer on November 2 2020 at the age of 82.

GB Railfreight very kindly offered a Class 66 to be named in John’s honour at Rail Live. 66764 will take the name Major John Poyntz Engineer, Railwayman, with nameplates donated by the Office of Rail and Road.

The ceremony will be conducted by:

Colonel (Retd) Steve Davies MBE

Nigel Harris, Managing Editor, RAIL magazine

John Smith, Managing Director, GB Railfreight

Ian Prosser CBE, HM Chief Inspector of Railways, Office of Rail and Road

Representatives of John’s former Corps took part in the ceremony, this included Guest of Honour Colonel Andrew Ryan TD, Colonel Reserves at Headquarters Royal Engineers, supported by WO1 Nathan Toms. Also in attendance were soldiers from The Royal Monmouthshire Royal Engineers and 170 Infrastructure Engineering Group. The latter is also responsible for 507 Special Team Royal Engineers (507 STRE) who are the Army’s specialist rail organisation. Many rail industry employees are members of 507 STRE, providing valuable expertise to military rail operations.

Members of the Poyntz family were also present at the ceremony.

The Network Rail Aggregates, Sleepers and Materials Recycling stand explained what happens to track materials once they are removed from the infrastructure. Our national recycling depots identified where assets are suitable for reuse, these are then graded and can be recycled back into the network. Other materials which cannot be reused are sold externally with the revenue generated helping to fund the operation of the railway.

The Network Rail Aggregates, Sleepers and Materials Recycling stand explained what happens to track materials once they are removed from the infrastructure. Our national recycling depots identified where assets are suitable for reuse, these are then graded and can be recycled back into the network. Other materials which cannot be reused are sold externally with the revenue generated helping to fund the operation of the railway.

Intelligent Infrastructure is Network Rail's digital asset performance management programme. We use technology to turn data into intelligent information so the frontline and supporting teams can work safely, smarter and seamlessly to deliver improved services for passengers and freight customers.

Intelligent Infrastructure is Network Rail's digital asset performance management programme. We use technology to turn data into intelligent information so the frontline and supporting teams can work safely, smarter and seamlessly to deliver improved services for passengers and freight customers.

Our network includes 20,000 miles of track, including 30,000 bridges, tunnels, and viaducts; thousands of stations, level crossings, and signals and we also manage rail timetabling for all of the Network Rail infrastructure.

By capturing and exploiting accurate data on the performance of railway assets, II will revolutionise the way Network Rail manages the network, shifting the business from traditional maintenance schedules to proactive predict and prevent regimes.

II will allow teams in the routes to gain clear evidence on where assets are, how they behave, how they degrade and when they are going to fail – allowing engineers to carry out the ‘right work, in the right place, at the right time.

Welcome to Technical Services. We deliver specialist engineering, asset management, systems analysis, modelling and rail test development services. We work closely with the regions, routes, central functions and industry colleagues to improve the experience of our passengers and freight users.

The teams at Rail Live included:

Elsew here on site at Rail Live, visitors met Network Rail’s Air Operations team for a ground-based demonstration of the high-tech cameras and equipment they use to deliver aerial surveys for their customers.

here on site at Rail Live, visitors met Network Rail’s Air Operations team for a ground-based demonstration of the high-tech cameras and equipment they use to deliver aerial surveys for their customers.

This included the helicopter-mounted cameras as well as visuals of the data pre- and post-processing for a better understanding of the ways it can be used to improve railway management and maintenance.

The team also brought a Drone for live demonstrations.

Twin helix =Excalibur Sleeper Bolt was installed into hardwood sleepers using just a handheld ratchet spanner and battery powered impact wrench

Pandrol demonstrated their Aluminothermic Welding process and new Autoseal moulds, within a heat-resistant see through booth, so visitors could watch from a reasonably close distance without experiencing any heat. The inside of the crucible was heated to a 2000 degree temperature, and then poured into bespoke moulds, shaped around the rail, which repaired the track. We also did some sawing and grinding of the rail, as part of this process.

Dura Composites proudly exhibited their Queen’s Award-Winning, high-technology composite product solutions at Rail Live 2021 on stand F20.

Guests found out why everyone was talking about Dura Composites’ new ground-breaking d2 product ranges. They also learned about their unique patents and designs, new material technology, manufacturing methods AND class-leading performance.

With a number of impressive demonstration units on show at Rail Live 2021, including a 9m by 6 m Dura Steel/GRP Hybrid solution and a 3m by 2.5m Hammond ecs Mountbridge Overlay solution, Dura Composites showcased how Glass Reinforced Polymer (GRP) composites can be easily deployed as anti-slip and height-adjustable platform surfaces to accommodate new rolling stock, refurbish existing platforms, accelerate new build infrastructure and improve overall passenger safety.

Incidents at the platform train interface (PTI) account for almost half of the total passenger fatality risks on the mainline railway network according to the Rail Safety and Standards Board (RSSB) and in the UK, hundreds of Victorian platform installations are out of gauge with current station design requirements. Traditional materials are seeing prices rocket and supply shortages due to the impact of the pandemic, meaning now is a better time than ever to embrace modern composites to help deliver Project SPEED’s aim of halving the time and reducing the cost of delivering critical infrastructure projects.

Dura Platforms can be installed rapidly by skilled contractors, require fewer possessions compared to a conventional re-build approach and allow for work to be carried out at difficult locations where a more traditional approach and heavy machinery would be prohibitive.

Guests came to see the Dura Platform demonstration units and discovered how this ground-breaking GRP solution cuts platform installation time by up to 65% and how its built-in adjustability helps easily rectify Platform Train Interface (PTI) stepping distance issues.

The Rail Live demo unit also included a broad range of styles of Dura Composites’ dagger canopy and soffit boards which mimic the appearance of traditional timber, but are lighter, simpler to install and require virtually no maintenance over their long design life. Ideally suited to heritage rail projects, the patented Dura Dagger Board design achieves a market-leading fire rating of B-s1,d0 in accordance with BS EN-13501-1 and provided both decorative and functional benefits for passengers.

Guests explored their static display of Road Rail Suction exaction System.

Showcased track excavation, backfiring and waste handing processes.

Showcased the use of Grinding discs on their stand.

Guests came to see their caged demo of their confined space drone capabilities.

Guests saw Hirds trespass alarm system sirens.

Guests viewed their lifting beam and breaking system.

Guests viewed their rubber level crossing system with anti-trespass panels.

Demonstrated their rail drill, sleeper drill and Pandrol clip insertion.

Demonstrated their latest innovative communication products and their capabilities.

Guests watched their live application of Technocreate: a cement free, lightweight foundation material.

Earplugs were at the ready for their Rail Saw cutting demo.

Demonstrated how to put AED safety into practice in a real life emergency.